Application area:

|

Pharmaceutical Industry |

| |

|

|

Cosmetics Industry |

| |

|

|

Food Industry |

| |

|

|

Chemicals Industry |

Range of products:

LIQUIDS (0,5 - 180 ml)

e.g. shampoo, cosmectics samples, bath extracts, ice lollies, oil, coffee cream, vaccines,...

CREAMS (0,5 - 180 ml)

e.g. skin cream samples, mustard, mayonnaise, ketchup, grease, gel,...

TISSUE PACKING (in all sizes and any kind of impregnation)

e.g. swabs, refreshing tissues, glass cleaning tissues, spectacles cleaning tissues, double bags, cotton tissues, ...

POWDER AND GRANULES (0,2 - 250 ml)

e.g. pharmaceutical products, salt, sugar, spices, pudding, soups, milk powder, cappuccino, instant coffee, coffee creamer, baker’s yeast, tobacco, detergents, spot removal salt, seed,...

SMALL PIECE GOODS

e.g. sweets, nuts, saccharine tablets, ball point pen cartridges, test stripes, medical suture, ...

Description of operation:

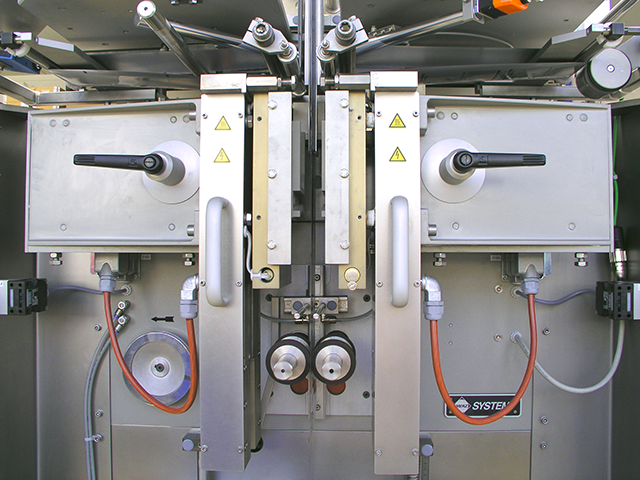

The MP2 is a vertically operating, fully automatic forming-, filling- and sealing machine for the production of three- and four-side sealed sachets.

The machine processes flexible, laminated foils from one reel or alternatively from two reels. In a sequence of single operations, the film is drawn off from the reel, cut lengthwise in the middle, then the two halves are guided face to face by a deviation triangle and sealed in U-form.

The ready-made empty sachet is filled then, conveyed vertically by one sachet length, closed at the top and cut off.

At the same time, a photocell control assures the exact positioning of the print.

The MP2 is a universal basic machine for the bag production. In combination with different product supply systems and dosing units, a wide range of products can be packed.